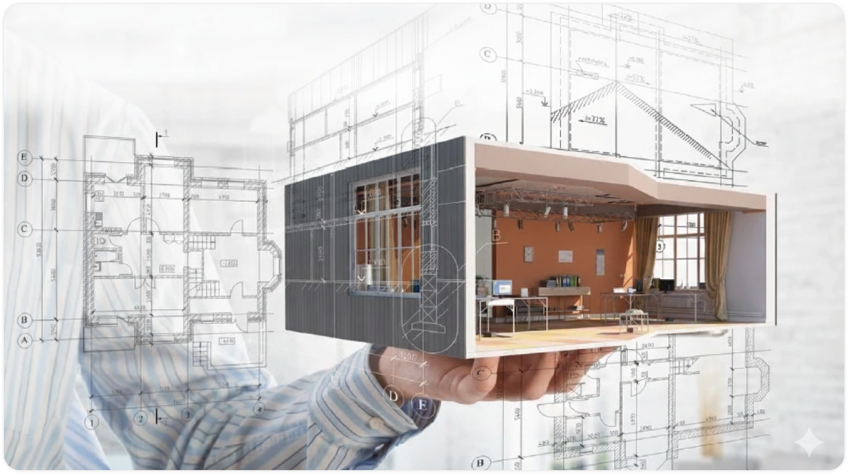

CUSTOM PROFILES & BESPOKE SOLUTIONS

CUSTOM PROFILES & BESPOKE SOLUTIONS

Custom aluminium extrusions represent solutions engineered to specific customer requirements not met by standard profiles. These profiles are designed and manufactured through custom die development, enabling creation of highly specialized geometries, integrated features, and application specific configurations. Custom profiles serve niche industries, high performance applications, and specialized projects with unique engineering demands. The custom extrusion sector values design flexibility, manufacturing expertise, and the ability to optimize profiles for specific functional and aesthetic requirements.

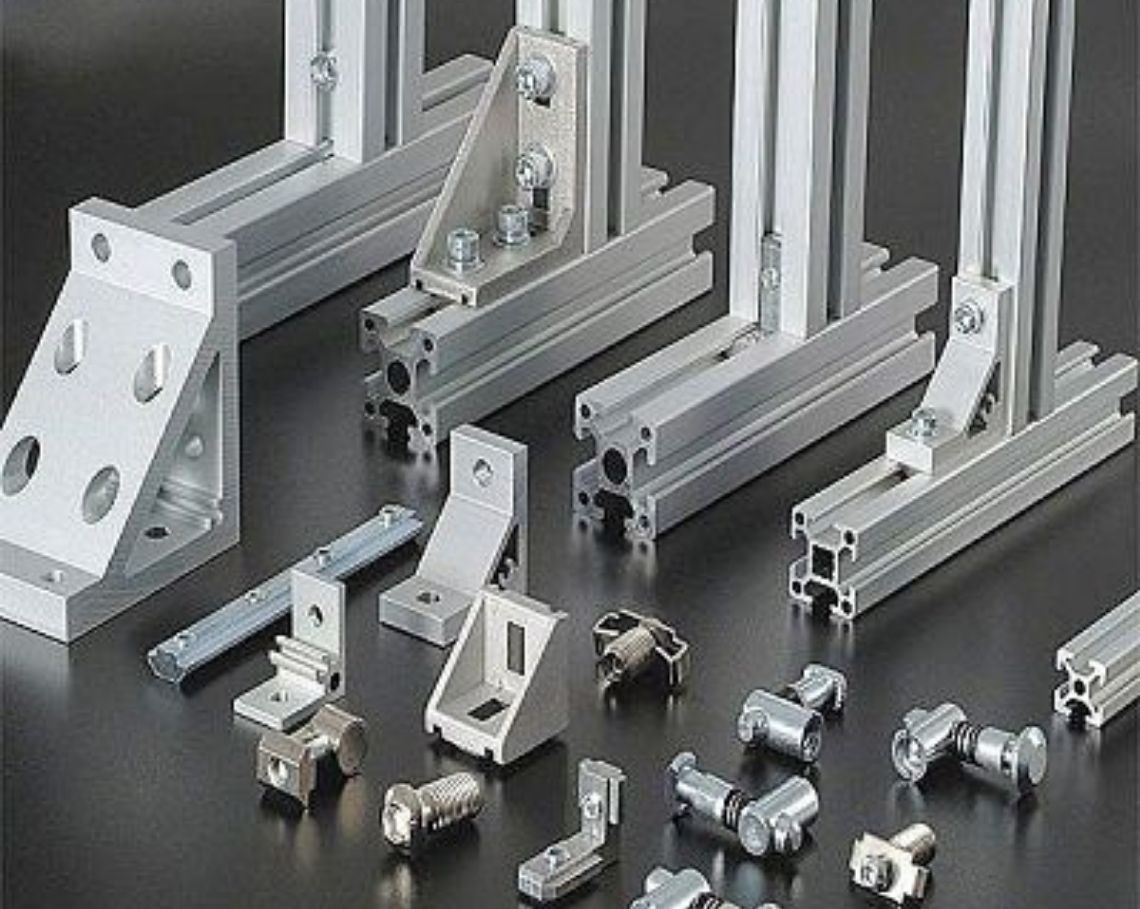

Capabilities & Applications

- Design-to-manufacturing : Custom die design and fabrication for proprietary profile geometries

- Integrated features : Grooves, slots, snap-fit elements, and internal channels designed into the profile

- Material optimization : Selection of specific alloys and tempers tailored to application requirements

- Size flexibility : Non-standard diameters, lengths, and cross-sectional complexity

- Finishing options : Custom anodizing, powder coating, plating, and surface treatments

Alloy Selection for Custom Profiles

- 6063 : Default choice for most custom applications; excellent extrusion characteristics and finish capability

- 6061 : When higher strength is required without excessive weight

- 6082 : Maximum strength for structural applications

- 5xxx Series : Specialized corrosion resistance requirements (marine, chemical exposure)

- 7xxx Series : Aerospace and high-performance applications requiring exceptional strength-to-weight ratio

Design Considerations

- Minimum wall thickness and draft angles optimized for extrusion

- Thermal break integration for architectural thermal performance

- Internal stiffening ribs and support structures

- Thread inserts and fastening points integrated into profile

- Complex multi-cavity designs for integrated multi-function solutions